Stockyard solution is designed to bring visibility across the organization and manage the stockyards optimally. It brings a systematic approach to plan and operate the stockyard activities and utilize man & machine efficiently. USIT uses 2D Radar scanning system to produce the real time information of the stockyard. The solution helps to eliminate problems like 'air reclaiming', 'ground digging' and 'collision risk' by continuously monitoring the stacking or reclaiming operation and their position on the real time basis.

The variety of operating methods and the multiplicity of materials has traditionally made it difficult to rely on anything else but skilled operators and to some extent semi-automatic or remote systems. However with the USIT technology, it is now possible to implement a completely unmanned operation for any combination of Stacker/Reclaimer. USIT offers a fully automated system which requires one operator presence in the central control room (CCR) to control a complete stockyard.

- Visibility

- Tracking

- Scheduling

- Stacking Assistance

- Cutting Assistance

- Anti-Collision

An effective and smart business decision can turn the situation of the company but it is merely a dream in absence of an integrated system with complete visibility on real time basis. The supply chain visibility of stock position at all the operational units, planning, logistics and operation can optimize the process and increase the productivity. The revolutionary technology brings the bulk inventory information online and on real time basis.

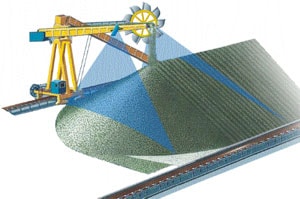

The stockyard solution offers a 3D graphical view of the actual stockpile boundaries and the current location of the equipment inside the yard on a real time basis. Changes in the stockpile surface caused by external interferences, such as dozers or pile collapses are also tracked and a quick overview of the inventory type and quantities stored around the stockyard together with a more detailed analysis tool to zoom and view cross- sections and effective utilization information.

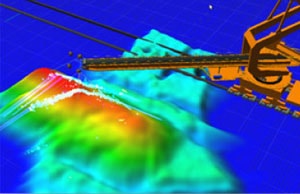

Data is valuable only when it is accurate and accessible on time. All the technological advancements for geological and mechanical modeling are for expertise and interest of the department but data collection is still being done in desperate system. The inventory tracking module keeps track of all material handled by the stockyard equipments. The properties like inventory volume, type, grade, density, stockpile boundary etc can be accessed through web based system on a real time basis. There are different colors to depict different stockpile with respect to their properties like grade, age, density etc. and it is for easy visual identification in the graphical overview. A reporting tool means you can extract vital information about any material stored in the stockyard database, e.g. material quantity, location or grade which is important when it comes to blending different grades of material to obtain a specified combined product, age etc.

As the demand arises, the system generates a schedule for required equipment and the same schedule is converted into work order for individual equipment. Each scheduled task comes with an estimated time to perform the work order and accordingly queued to perform the Task. It helps to track the equipment performance and guide the operator to execute the task without any manual intervention.

This feature allows to calculate the space requirement to stack incoming inventory. According to the ship/rake arrival plan, the system receives dispatched weight manually and then it will calculate the space requirement and suggest the yard area where inventory can be stacked. It also assists to control the boom height while stacking to control dust.

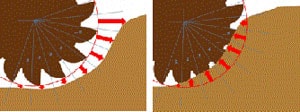

The Cutting Span Depth Estimation feature allows to monitor the depth of bucket cuts into the stockpile. To enable this control, the radar array measurement section is virtually split up into n equal-sized zones (illustrated by blue lines in image below) that are arranged within an angle of about 100° degrees. The zones are numbered from 1 to n and from the lowest point of the angle to its peak. The depth of the cutting circle into the stockpile is continuously updated and returned for all zones.

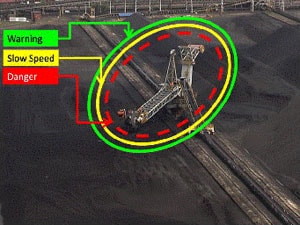

The anti-collision and collision avoidance assistance uses the radar positions and automatically alerts an operator if machines are within the vicinity of the outer allowed operations. The system will generate alert and beep in case it runs in manual mode and stops equipment in case it is on auto mode. The system provides 3D visualization of anti-collision zones in 3D.